Turning a corner in a ceramic installation is a design opportunity and sometimes a budgetary challenge. Balancing these two factors is key to making good design decisions for your installation.

Inside or Outside

There are two types of corners, inside and outside. An inside corner is the most common where two walls meet as in square rooms with four corners. An outside corner is where the corner projects outward into a space. In the above kitchen there are inside corners in the stove nook and outside corners on the pillar detail.

Inside Corners

The inside corner is the easiest to make. We recommend using onsite installer cuts. As the tile hits the conner cut the tile to fit and then take the remaining piece and place it on the other wall surface with a minimal joint in the corner. This will give the appearance of full tile rounding the corner. If the cut piece is a sliver I would not use it.

This method has two main advantages. It uses standard tile rather than special pieces. Also, it is common for walls to settle and move in different directions over time. Using a cut joint in the corner will allow the walls to move without breaking a tile. If a one piece inside corner is used and attached to both walls it will break if the walls settle differently.

Outside Corners

There are a few ways to round a corner depending on your budget and design intent.

My favorite way to round an outside corner is to use an actual corner tile. When using corner pieces you should start your installation at the most visible corner by alternating the direction of the ‘long leg’ of the corner piece. This will start the pattern off correctly in both directions.

Another method of turning a corner is to use edge glazed tile. In this simulated image edge glazed bricks extend one tile thickness past the corner and regular bricks are cut to reestablish the running bond pattern as the brick continues on to the other wall surface. Contrasting grout in this image exaggerates the grout joints, in practice this method yields good visual results without special corner pieces.

With the popularity of ultra large format tile in recent years the usage of extruded metal corner stips has become more popular. Schluter Systems is a popular maker of these metal trims with many options available.

To Miter or Not to Miter

Another corner option to consider is the onsite miter cut for outside corners. The benefit of the onsite outside miter cut is that it can be done with standard pieces of tile. This is often the only way to do an outside corner as many product lines don’t include corner pieces. In this method the installer makes 45 degree miter cuts on two pieces and joins them on the corner, often without a joint. The down side of this approach is that the corner is often very sharp and easily chipped.

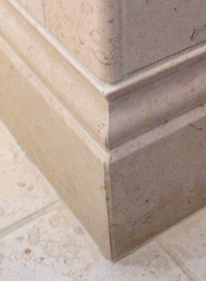

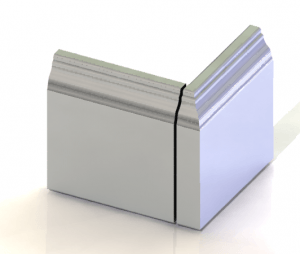

If given the choice we prefer to use the Stop and Return corner method for larger base and trim pieces. In this method, a Stop and Return end tile is placed one tile thickness past the corner and a second straight piece is placed on the next wall surface.

With lots of alternatives available there is one that is right for your project’s design and budget.